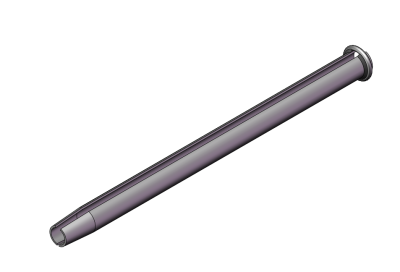

Friction Bolt -42-1800mm

- Friction Bolt -42-1800mm is roll-formed into a C-shaped bolt with a slot by a high tensile steel band, which one end is tapered for easily inserting the bolt into drilling hole. The other end is welded a ring to hold the bearing plate.

- -Has high shear and tensile strength.

- -Usually combined with domed plates, provides anchoring force for rock strata.

- -Friction bolt reference to the AS/NZS1594 / ASTM A1011 standard.

Friction Bolt -42-1800mm Functions

Friction Bolt -42-1800mm is an efficient ground support slement commonly used in underground installations that work primarily through friction,providing immediate reinforcement.They consist of a longitudinally grooved steel tube,with one end tapered to facilitate easy insertion into a borehole.

Friction Bolt -42-1800mm Features&Advantages

Independent supporting without plate

Easy for installation

Simple design,cost saving

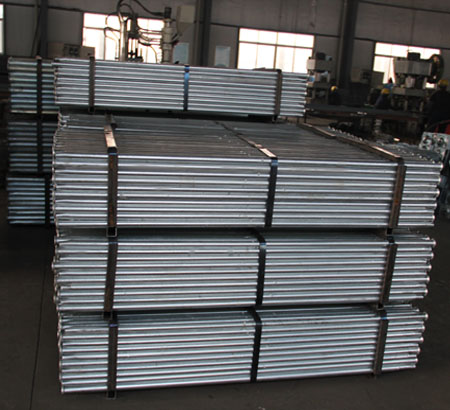

Available in black,cold galvanizing or hot dip galvanized

Made from high strength steel band

Immediate frictional Support in axial and radial

Friction Bolt -42-1800mm Mechanical Properties

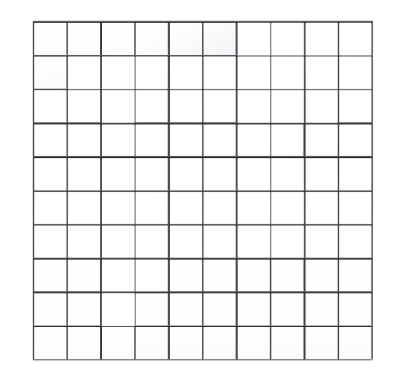

| Technical Data | TRFB33 | TRFB39 | TRFB42 | TRFB47 | |

| Drill hole diameter (mm) | 30-32 | 35-38 | 38-40 | 43-45.5 | |

| Min.Yield strength (kN) | 80 | 90 | 100 | 120 | 135 |

| Min.Tensile strength (kN) | 100 | 120 | 132 | 165 | 180 |

| Typ.Tensile strength (kN) | 120 | 130 | 150 | 180 | 200 |

| Elongation (A%) | ≥20 | ≥20 | ≥20 | ≥20 | |

| Typ.Anchorage (ton/m) | 4-6 | 4-7 | 5-8 | 6-10 | |

| Bearing plate (mm) | 150X150X4 | 150X150X4 | 150X150X4.5 | 150X150X5 200X200X5 | |

Friction Bolt -42-1800mm Accessories

Bearing plate,Driver,Pull collar.

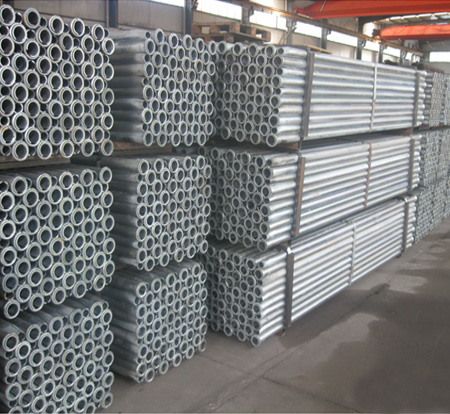

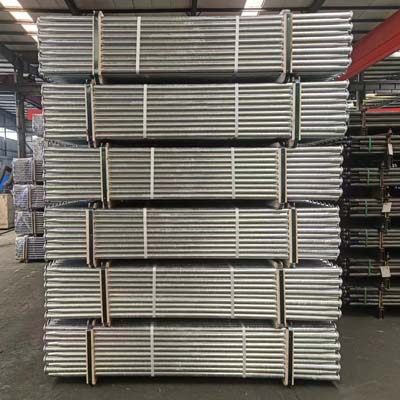

Friction Bolt -42-1800mm Package

Package:100pcs — 300pcs each bundle as specified

Friction Bolt -42-1800mm Applications

Mines

Tunnels

Slopes

Places where need ground support

How to work

The nature of mine need to be evaluated.

Choose the applicable bit and drill a gap in accordance to bolt diameter,bolt length,and drilling procedure,and size is at least 150mm longer than size of friction bolt.

Place a plate onto friction bolt (dome in opposition to the ring,tapered end at front).

Friction bolts have to be mounted as perpendicular to the rock surface.

Put driver dolly into the bolt and power friction bolt into the gap till the plate is firmly in opposition to the rock surface.

Do not pound on the friction bolt when plate tightly fixes on the rock surface,in order to keep away from harm of friction bolt end.

Pull exams shall be carried out to decide the preliminary anchorage of the friction bolts after installation.