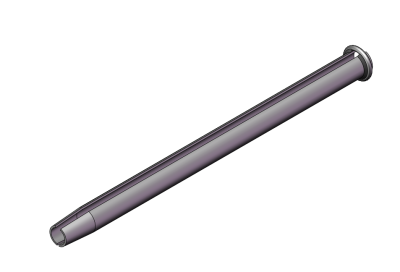

Spiral Rock Bolt

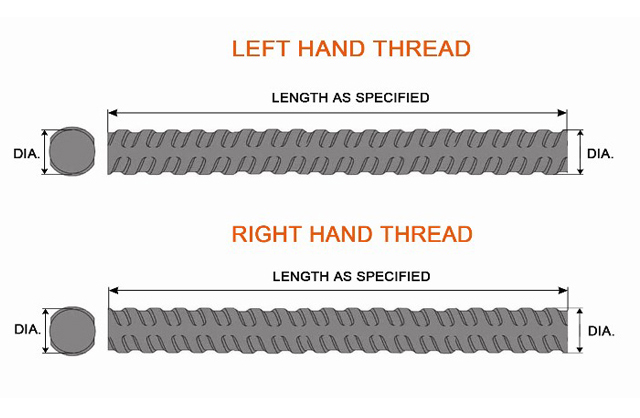

- -Available in left hand or right hand tread.

- -Higher thread ribs mix resin better and improve anchorage.

- -Suitable for using with either resin cartridges or cement grout.

- -It has equal strength on the entire length.

- -Due to continuous thread on entire length. the nut can be fastened upward at any place. This will increase the material utilization ratio and save cost.

- -Available in black or hot dip galvanized.

Spiral Rock Bolt Functions

It features a high-strength metal bolt body, continuous threads rolled throughout the entire length, and uniform strength throughout the length. The fastening end is equipped with prestressed washers and ball shaped nuts, which makes it material-saving, labor-saving, and uniform strength. Its features include high strength, reasonable structure, large preload, the ability to automatically adjust the force direction, increase the constraint force on the surrounding rock, and achieve rapid mechanical installation. In addition, it comes in various specifications and can be processed into different lengths of rod body threads according to requirements. The tail end can be cut at an Angle or by a flat cutting process.

Spiral Rock Bolt Mechanical Properties

| Diameter | Yield Strength | Tensile Strength | Elongation A % | Mass Meter | Core Dia | Major Dia | |||||||

| Min | Typ. | Min | Typ. | Min | Typ. | ||||||||

| 20mm | 515 MPa | 162KN | 560 MPa | 176 KN | 630 MPa | 198 KN | 710 MPa | 220 KN | 18% | 24% | 2.46 KGS | 19.5mm | 22.5mm |

| 22mm | 525 MPa | 199KN | 590 MPa | 224 KN | 652 MPa | 247 KN | 761 MPa | 289 KN | 18% | 24% | 2.98 KGS | 21.2mm | 23.8mm |

| 25mm | 550 MPa | 269KN | 610 MPa | 298 KN | 684 MPa | 335 KN | 798 MPa | 391 KN | 18% | 24% | 3.85 KGS | 24.8mm | 28.5mm |

Spiral Rock Bolt Bearing plate

Spiral Rock Bolt Accessories

Domed nut, hex nut, anti-friction washer,domed ball

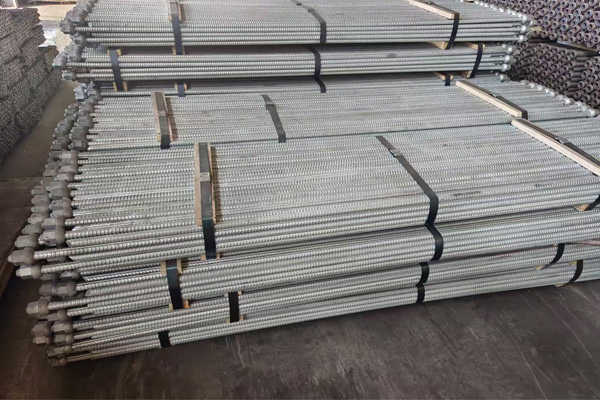

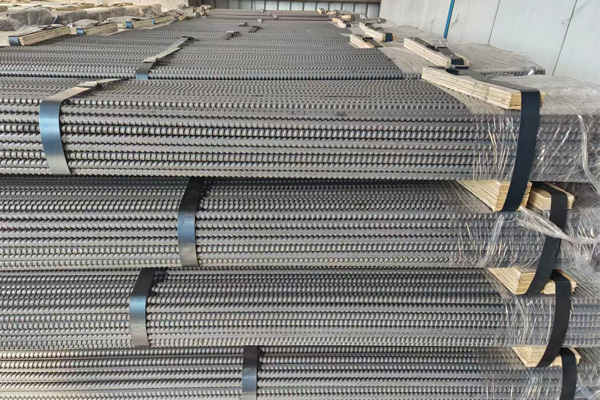

Spiral Rock Bolt Length and Package

Bolts are packaged in bundles.

Bolt

fittings, such as nuts, anti-friction washers and domed balls, are

supplied fitted to rock bolts in the configuration requested.

How to work

1.Drill a hole with punching according to the requirement of design.

2.Use wind pressure to blast the hole rock powder

3.The hole diameter is 6-12mm bigger than the bolt diameter

4.Put rebar anchor bolt into the hole bottom and start the mixing device.Mixing time is to be rigidly controlled according to the requirement of resin anchoring agent.

5.Screw the nut tightly when time is up.

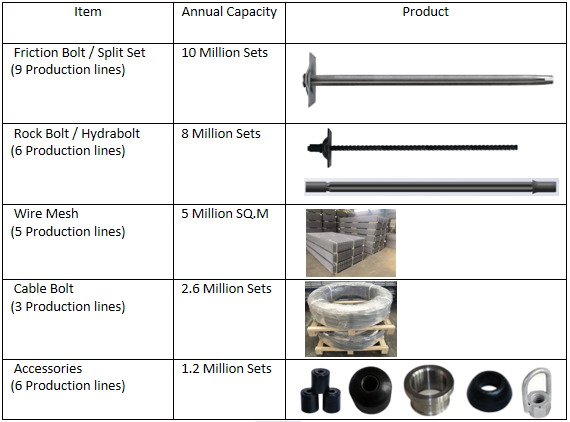

Tonry with the manufacturer specialized in developing new support products,according to different requirements of a variety of customized products from different mining companies.The following is the annual production capacity of several major products.