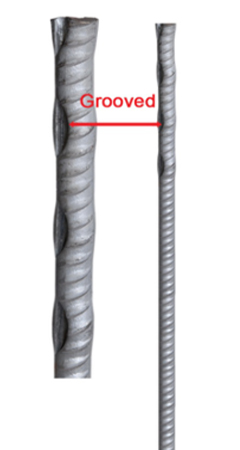

Fully Grouted Support Bolt

- -Available in various of bar configuration.

- -The grooved configuration at the end of the bolt ensures that the bolt is located in the middle of the bore hole.

- -The grooved configuration will improve resin mixing and consequently provide high bond strength.

- -Using a pin nut device, nut could help drive the bolt to mix the resin.

- -Used for permanent ground support.

- -Install quickly and easily using mechanized tools

- -Available in black or hot dip galvanized.

Fully Grouted Support Bolt Functions

The Fully Grouted Support Bolt, which also named "Grooved Bolt" is manufactured from

full thread bar, TR-Bar, or Rebar. One end is stamped into 3½ paddle

configuration and the other end is rolled thread. Being used with plate, domed bolt,anti-friction washer and nut, Grooved Bolt can be an effective rock reinforcement system for underground rock support.

Tonry speciclized in developing new support products, according to different requirements of a variety of customized products from different mining companies.

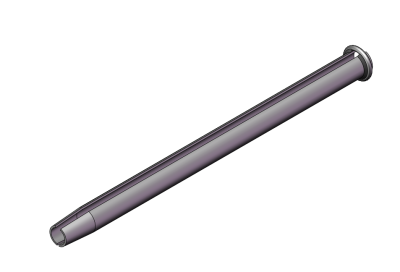

Bearing plate of Fully Grouted Support Bolt

Fully Grouted Support Bolt Accessories

Domed nut, hex nut, anti-friction washer,domed ball

Installation Guide

1.Drill a hole with punching according to the requirement of design.

2.Use wind pressure to blast the hole rock powder

3.The hole diameter is 6-12mm bigger than the bolt diameter

4.Put anchoring bolt into the hole bottom and start the mixing device.Mixing time is to be rigidly controlled according to the requirement of resin anchoring agent.

5.Screw the nut tightly when time is up.

Fully Grouted Support Bolt Length and Package

1.Pack the bolts into bundles.

2.Bolt fittings, such as nuts, anti-friction washers and domed balls, are supplied fitted to rock bolts in the configuration requested.

Grooved Bolt Applications

Mines

Tunnels

Slopes

Places where need ground support