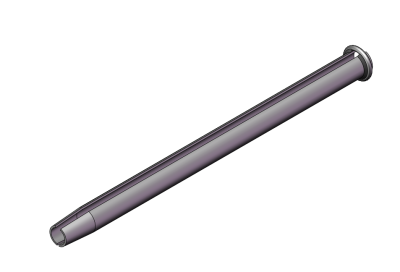

Sharp End Anchor Bolt

- -It made of hot rolled ribbed bar. Higher thread ribs compared to others bars,mix resin better and improve anchorage.

- -Suitable for using with either resin cartridges or cement grout.

- -Due to continuous thread,nut can be tightened at any place.

- -Privide the same tensile strength on the entire length.

- -Available in black or hot dip galvanized.

Sharp End Anchor Bolt is applied in mine roadways and underground engineering surrounding rock support, which can ensure the stability of mine roadways and underground surrounding rock. The entire length of the rod body is continuously threaded by rolling, with equal strength throughout. The fastening end is equipped with prestressed washers and ball-end nuts.

Sharp End Anchor Bolt Mechanical Properties

| Diameter | Yield Strength | Tensile Strength | Elongation A % | Mass Meter | Core Dia | Major Dia | |||||||

| Min | Typ. | Min | Typ. | Min | Typ. | ||||||||

| 20mm | 515 MPa | 162KN | 560 MPa | 176KN | 630 MPa | 198KN | 710 MPa | 220 KN | 18% | 24% | 2.46 KGS | 19.5mm | 22.5mm |

| 22mm | 525 MPa | 199KN | 590 MPa | 224KN | 652 MPa | 247KN | 760 MPa | 289 KN | 18% | 24% | 2.98 KGS | 21.2mm | 23.8mm |

| 25mm | 550 MPa | 269KN | 610 MPa | 298KN | 684 MPa | 335KN | 798 MPa | 391 KN | 18% | 24% | 3.85 KGS | 24.8mm | 28.5mm |

Sharp End Anchor Bolt Bearing plate

Round plate, domed plate,combi plate

Sharp End Anchor Bolt Accessories

Domed nut, hex nut, anti-friction washer,domed ball

Sharp End Anchor Bolt Length and Package

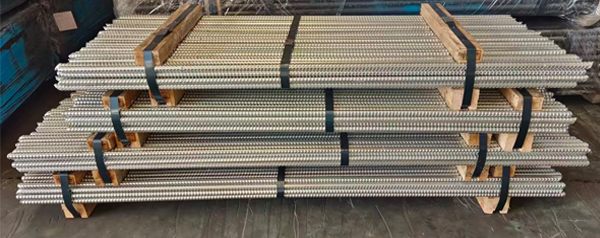

Length:1.8m/2.0m/2.2m/2.4m or as requested

Package:Bolts are packaged in bundles.

Installation Guide

-The nature of the ground must be evaluated.

-Drill a hole with punch according to the diameter of rock bolt,the diameter of hole id 6mm-12mm bigger than the rock bolt.

-Before installation,the hole should be blown and cleaned by compressed air.

-If use resin,push the resin into the hole by hand or machine,ensure it could reach to the top of hole.

-Rotate and push the bar,when the plate reaches the roof,spin bolt to ensure that mix the resin completely.The mixing time should be controlled strictly according to the using in struction of resin.

-Screw the nut tightly when time is up.