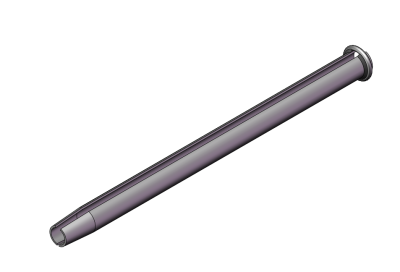

Mesh Strap

- -Mesh Strap can improve load distribution between roof bolts.

- -Accommodates all bolt spacing patterns.

- -Large support areas can be created by overlapping sheet edges.

- -Corrosion protection can be provided by hot dip galvanizing.

- -A variety of lengths and widths are available and can be customized according to your requirements

Mesh Strap Introduction

Mesh straps are used in unstable ground conditions with seismic activity. They are used to improve and ensure a better connection between surface supports and bolts. These ties support broken ground between rocks by providing a continuous grid between anchor points. Osro strapping has been used in the mining field for many years since its invention, providing on-site support to mines around the world.

Mesh Strap Key Features

1.High energy absorbing.

2.Allows for movement without weakening the integral mesh strength.

3.Pig tail cross wire design allows for multiple take upon bolts.

4.Available in black or hot dip galvanized.

5.The longitudinal wire strand is able to slip under load conditions through the cross wires to distribute load over several bolts.

| Properties | Technical Specification |

| Longitudinal Wire Diameter | 10mm |

| Cross Wire Diameter | 6mm |

| Nominal Length | 6000mm |

| Norminal Width | 300mm |

| Wire Aperture | 75mmx150mm |

| Yield Strength of Wire | 400MPa Min |

| Tensile Strength of Wire | 500-750MPa |

Mesh Strap Package

1. Steel or Fiber strapping.

2. Bundle sizes to suit the customer, generally packs of 50pcs.