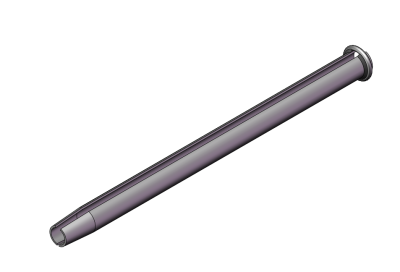

Friction Roof Bolt

- -The raw material is made of high-strength alloy steel strip.

- -High yield strength and high tensile strength.

- -It has high shear and tensile strength.

- -No anchoring agent is required.

- -Simple installation procedure,save cost

Friction Roof Bolt

Friction roof bolts are made of high-strength steel, with extremely strong tensile strength, and can easily cope with various complex geographical conditions. The unique pipe joint design makes installation extremely simple, without the need for complicated operations, greatly saving time and labor costs. Moreover, it has an excellent anchoring effect and effectively enhances the stability of the surrounding rock.

Friction Roof Bolt Technical advantage

High-strength plate beraing capacity,the rod body than retaining ring pull off the bearing force than pole.

Method of application

1.According to the requirement of design,drill a hole with punching

2.Use wind pressure to blast the rock powder of the hole

3.Rod anchor plate fitted with a shock will bolt into the hole drill

Friction Roof Bolt Mechanical Properties

| Technical Data | TRFB33 | TRFB39 | TRFB42 | TRFB47 | |

| Drill hole diameter (mm) | 30-32 | 35-38 | 38-40 | 43-45.5 | |

| Min.Yield strength (kN) | 80 | 90 | 100 | 120 | 135 |

| Min.Tensile strength (kN) | 100 | 120 | 132 | 165 | 180 |

| Typ.Tensile strength (kN) | 120 | 130 | 150 | 180 | 200 |

| Elongation (A%) | ≥20 | ≥20 | ≥20 | ≥20 | |

| Typ.Anchorage (ton/m) | 4-6 | 4-7 | 5-8 | 6-10 | |

| Bearing plate (mm) | 150X150X4 | 150X150X4 | 150X150X4.5 | 150X150X4 200X200X4 | |

Friction Roof Bolt Method of application

1.According to the requirement of design,drill a hole with punching

2.Use wind pressure to blast the rock powder of the hole

3.Rod anchor plate fitted with a shock will bolt into the hole drill

Friction Roof Bolt Accessories

Bearing plate,Driver, Test Pull collar.

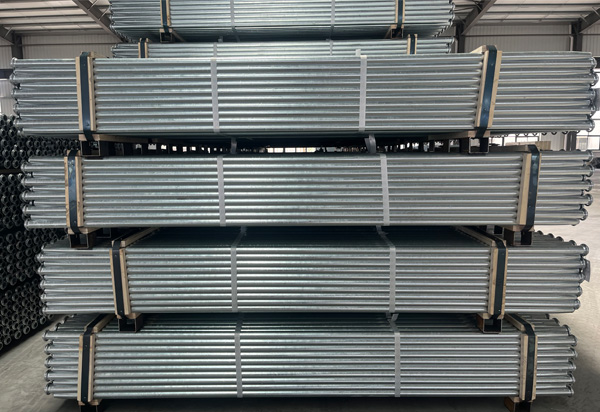

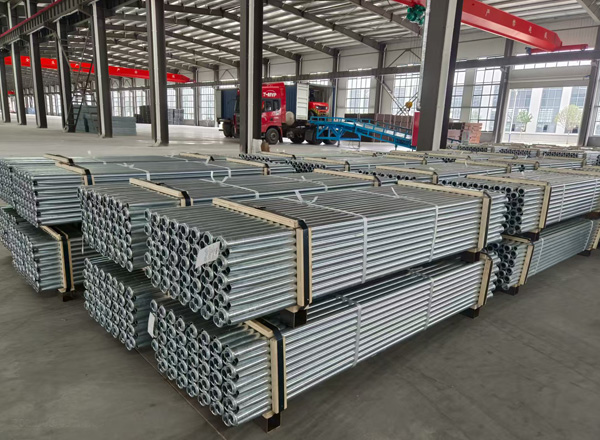

Friction Roof Bolt Length and Package

Length:450-3000mm as specified

Package:100pcs — 300pcs each bundle as specified